We made ours 10ft wide. Not so heavy to move, not so narrow they could run out easily. Pressure treated lumber.

Do you have access to a table saw or circular hand saw? We purchased 10ft lengths of 4" x 4", then cut off those 4 corners with the saw. Table saw is nicer, but the circular saw works too. BIG THING is to cut slowly, NOT push on the saw hard, while cutting thru the wood. A tip is to open the long cut with a piece of wood between the rail and cut off corner, behind you. This prevents saw blade being bound tight in the cut, making saw woork too hard as it cuts. Cutting the 4 corners evenly will leave you with an 8 sided rail, no sharp corners. You may want to make extra rails, they are handy without the X ends as trot rails on the ground, jump rails. Sell them to others at a profit, to pay for your cavaletti. Jump rails get broken all the time, they need new ones.

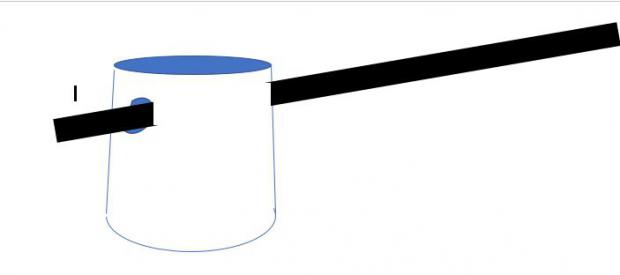

Husband did the German style Xs, different height on each side of the X, for three settings of rail height. Bolted thru the center of X into the rail.

I personally hate PVC for rails. They do not stay straight if left in the sun. The can get brittle, shatter when bumped, throwing the sharp edged pieces all over to land on! Saw that happen at a pony club meeting with our horse! She missed getting cut, but I hauled our own wood rails to meetings after that!! She also had learned bad habits with the PVC, dragging a hoof to check plastic or wood? She then would not jump, just blast thru the plastic rail jumps. Wood, she jumped in good style, clean. It was worth hauling the wood rails to prevent bad habits escalating! And over time, the kids avoided the PVC jumps because their horses were also developing bad habits!