Because this is the summer when everything on the farm will not work - my Pyranha fly system is shooting out liquid where the emitters connect to the tubing in two stalls. I am thinking that is because the emitters are clogged. I was trying to unscrew the emitters from the tubing but it won’t work. Maybe they are corroded or maybe they do not unscrew? I thought I would soak them in vinegar to see if that would unclog them but if I can’t get them down??? I think the last time I had a clogged sprayer I just cut it out and I had enough play in the tubing to insert a new sprayer. I am not sure that will work this time. Any suggestions?

When I worked at a barn with a Pyranha system we had to cut them out and replace them. What kind of water are you putting in your system? We had to use distilled water, the well water would kill the system instantly.

The mister nozzles head can be unscrewed but if the line is leaking where it is pushed into the nozzle it has to be cut out to replace, to help keep the system clean change the pickup filter in the tank. We also use compressed air to blow the system dry when we shut it down for the winter to reduce the effect of freezing on the system.

I am amazed at what a system costs these days, back when we bought it in 1991 it cost $599 including shipping, today it is close to $2,000 But the 55 gallon refill costs the same as it did in the 1990s.

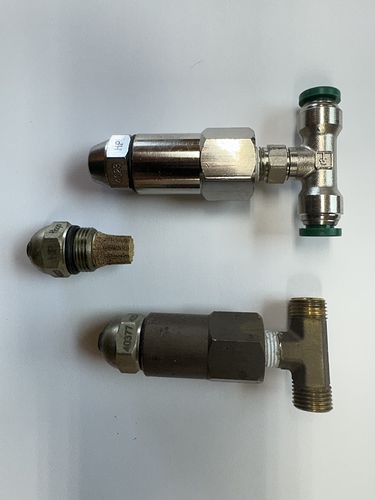

Do you have the older style body (bottom of picture) which uses compression fittings to connect to the plastic tubing, or do you have the newer style that uses push-in connections (top of picture)? The screw-in nozzles fit either type of body.

Are you trying to unscrew a compression fitting from the tubing, or are you trying to unscrew the nozzle assembly from the body?

I don’t think it is my city water. A few years ago I had some hay slip down into the barrel when it was full of fly spray. I tried to use a fish net and scoop as much out as I could and last year I bought a new filter because the old one was filthy. I think some of that crud escaped into the tubing.

The nozzles I have are like the top nozzles. I was trying to unscrew the bottom contraption from the “T” part. It turns but does not unscrew. I have not tried to unscrew the bottom piece like you show in the middle. I did not know it unscrewed. I will get back on my ladder and try that. So far nothing comes apart. The solution is spraying out from both sides of the top T-part of the emitter so I am assuming the nozzle is clogged up. And yes - when I set up the system the tubing pushed into the compression fitting like the top picture.

Another note. If you need to add more plastic tubing length you can connect two tubes usinga compression fitting. But I recently did this in several spots and leakage at the connectors was a problem. Then I discovered that I should have used plastic ferrules rather than the metal ones that came with the big box store connectors. Metal ferrules are for copper tubing. When I used plastic ferrules the leakage problem was solved.

It should unscrew but that upper part going into the T body is really, really tight. I disassembled a new one just now to get pictures for you.

But if it is clogged I think that just removing the nozzle part is all you will beed to do. Once you have the nozzle off, the brass screen unscrews from it and the screen is likely what is obstructing flow and is the pRt you need to clean.

Where did you get plastic ferrules? I may have enough length of tubing in the run to be able to cut it out like last time.

Still trying to get the nozzle off. Trying to find WD40 or corrosion spray. As long as I know it will come off I will try a little harder.

Thanks!

Hope you know that pushing in the blue plastic collars where the plastic tubing inserts allows the tubing to be pulled back out. No need to cut the tubing to remove a mister assembly, and you can reinsert the original tubing to replace with a new or a cleaned mister

This allows you to take down the mister assembly and work on it on a workbench rather than from the top of a ladder.

I will check that out. I could not get the mister to loosen up and on top of the ladder it is HOT! If I can get it down that would make life so much easier. Hard to hold on to two wrenches standing on the ladder and remembering if I turned the wrench left or right to loosen. If I get this figured out I won’t forget it - that is for sure.