I would like to put in new fence posts where they have rotted out (35 yrs) but would like to reuse the fence boards that were nailed on and put them back up. Anybody have any ideas how to go about this? Hate to waste perfectly good boards.

I use a crow bar to pry nailed boards off. Then hammer the nail out of the board from the back.

No magical way. Hopefully the original nails are not countersunk deeply so that you will be able to get a prying tool underneath the heads. And pray that they aren’t ring shank nails.

If you get in a bind and cannot pry, one alternative is to use a saw to cut the board just short of the nails. You will end up with a shorter fence board, but if you are lucky the post spacings aren’t exactly the same everywhere and you will find a place where the now several inches shorter oak board can still be used. You’ll still need a few new longer boards if you do this.

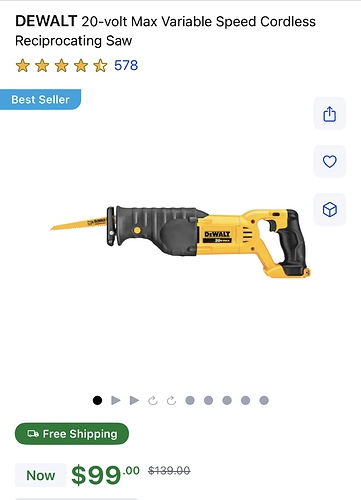

Another approach to boards that cannot be pried is to use a reciprocating saw blade inserted between the back of the board and the post to cut the nails.

we had to do this before, and what the other two posters said. Now we use screws to put the boards up. Easier to put up and easier to remove or replace as needed, plus the screws wont back out like nails can.

You might be able to use a reciprocating saw (aka sawzall - as in “saws everything”) to get between the boards and the nails, and using metal cutting blades just cut through the nails. It’s how I take apart pallets for projects. I used to use a pry bar but ugh, so much work…. The sawzall just slices right through the nails.

ETA - yes to screws. Deck screws using T25 bits are superior to flathead or philips type. I no longer use nails either.

Pic as an example, not promoting the brand

screws, get the same head always

We have over the years got at least five variations each requiring its own special bit. And yes to the reciprocating saw, it males life easier

Its not practical to say “same head always” really. For the structural SPAX screw, increasing length goes from T20 - T25 - T35. Same exact screw type, just length changes.

Everything else I try to get the square head, or the philips that will accept the square. Less likely to strip.

A note regarding screw installation: my original fence installers were pretty heavy-handed and countersunk most of the torx head screws way too deep, That made getting the torx bit for removal a puzzle about the angulation of the screws and getting the bit aligned properly by braille. When replacing boards I just insert the screw head flush with the board surface. Makes my life easier since I own a butt rubbing fence board breaking draft cross gelding and he tends to destroy the same boards over and over,

Yes, I know sometimes with a slightly twisted new board the screw does end up countersinking itself deeply while pulling the board flush with the post.

Yeah don’t counter sink them. It makes another place for water to get in .just put them flush

Maybe pull one board off and see how it goes. Oak boards can become very hard being out in the sun for 35 years. It could be very difficult to pull the old nails out and hammer new ones in. The suggestion to cut them off and put the posts a little closer might be the way to go. Whether you use nails or screws, think about drilling a small pilot hole first. It will keep the boards from splitting.

I just did this six months ago - had about half of my fence replaced entirely, and about 25 posts elsewhere. I saved the best boards for patching up the old part of the fence.

Removal was either a strong whack from the back side with a sledgehammer or prying off with a very large pry bar. Then I used a hammer and a very small pry bar to straighten out the nails and hammer them backwards through the boards until there was enough to remove them the normal way from the other side. Those old boards are very difficult to nail new nails through, but with the old holes right there, it worked out just fine. I did need to do some cutting or choosing of boards since I was putting them back up in different spots than where they came from. I had a drill handy for pilot holes for the nails if I needed a new spot. That old wood was really hard and tended to bend nails. Mine were about 25 years old.