…. Or have spouses that are more handy to help

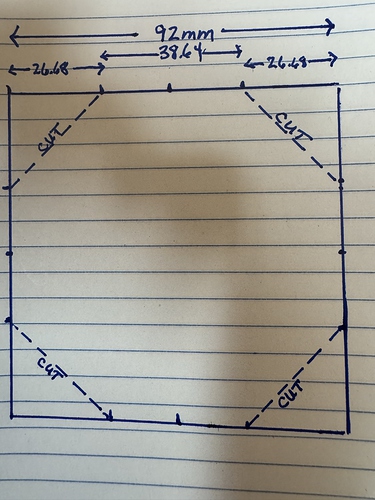

Has anyone used this technique to make 4x4 posts into octagonal rails?

We’re looking to build a small course (approximately 8 fences) but have never done this before so looking for feedback.

The husband LOVES tinkering with woodworking and is looking forward to this not so small project. He happily told me today that the jump cups have been sandblasted and painted and they’re ready.

I’m debating between 10’ and 8’ rails. The outdoor is rather large and could accommodate 10’ rails no problem, but of course 8’ lengths leave more room to move around the jumps, or have fences on the quarter line in addition to lines on the rail.

We’ve looked at pictures of jump fill online and will have no problem making gates, planks and boxes but it’s been a discussion on the best way to make the poles.

If anyone has any tips, tricks, or experience doing this I’d love to hear!

and my horse got much more pole work because I didn’t kill my back moving them. Sadly, I had to move barns but the new barn also has some landscaping timber poles and some 8 ft poles that aren’t as heavy so all is not lost.

and my horse got much more pole work because I didn’t kill my back moving them. Sadly, I had to move barns but the new barn also has some landscaping timber poles and some 8 ft poles that aren’t as heavy so all is not lost.