Kinda starting to think about fence for our new farm. I will be fencing in about 7 acres with a split down the middle. I am considering v-mesh with a top board. My idea is to have someone set the posts and I will do the fencing. Post set at 8’ and using 16’ length 2X6 on the top, no climb 5’ mesh beneath. The top boards will be easy but I am concerned on getting 100’ rolls of mesh nice, smooth and tight. Any tips? I could look at YouTube, lol

You might need to use a fence stretcher/tensioner. That’s just too much hard work for me, which is why although I love that kind of fence if I’m doing it, it’s 3 or 4 board. I almost would rather set the posts and use an auger to drill holes, and pay someone to put the wire up.

Also one thing I found after many years of building and maintaining horse fence is that FOR ME having the top board be 16’ on 8 foot posts was more problematic. Mostly due to warping over time and the inevitable breaking of a 16 foot board. And it was never in 8 foot sections. It would always be 15 feet along …. Horse breaks the board. Now you have to get the sawzall out cut it off close to the good 8 foot section and replace the other 8 feet. Pain in the butt. I am Florida and the wet the humidity and the heat really wreck havoc on long boards (warping)

If you have suitable soil, not rock, ledge or other almost impervious underground, have your posts drIven in with a mechanical post driver. No digging or augering to make post holes, no back filling or concrete to hold posts in place. Post driver gets them in fast, they stay tight. Still using 90% of those posts a lot of years later.

We hired our fence work done, after learning new husband and i could not work well together! It was like he spoke a foreign language and never said a direction the same way twice!! I worked with labor guys at my job, had no problems following or giving them directions during our work tasks. . Better to pay for the fence work!! Everything was completed quickly, looked terrific. I believe the post driver broke one post out of MANY, when post hit a big rock. They had to cut off 2 posts that somehow were not in the straight line. Could not pull them back out, they were that tight.

16 foot 2 bys are going to be a pita to work with and so likely to warp and crack. Top with 16 foot fence boards instead. Rough cut one by six.

Stretching mesh is one of those things that’s worth hiring out.

You might consider something like centaur rail for the top “board.”

Wooden boards are a constant maintenance headache. Consider vinyl rail for the top ‘board’. And if it’s a 4’ fence, the kind with electric on the top edge.

Concrete and brace your corner posts. The v-mesh or non-climb must be under tension to work correctly, and it will pull your posts over and sag if you do not get the corners right.

2by4 no climb will be in 100ft rolls, V Mesh is usually in 165 ft rolls (10 rods measurement)

Field fencing is usually in 20 rod rolls (330 ft)

Dead level, square, plumb posts that won’t budge. Otherwise the wire won’t be smooth. The H braces will need to be set so you can pull the next roll against them and spaced to take into account the waste under the tensioner board / clamp.

It can be done but it’s gosh awful work.

I like deck boards for the top rail personally.

Interestingly, 2-8’ boards are cheaper than a 16’ section.

Shorter boards are cheaper because they are easier to make from short log sections. 16ft logs are harder to come by for sawing boards from. So one-piece length will usually cost more than two boards equaling the one board length.

But I’m so scared to get a quote for installed fence.

I get that. I purchased materials, rented an augur (ours kept breaking shear pins and it was impossible to use), and then we fought for a while about getting the line straight, etc. and gave up and hired a crew. As much as it costs to pay someone else to do fencing, it’s worth it because you look at it every day (so it needs to not suck) and it needs to be strong/reliable to keep horses in or you’ll never sleep. Just my 2 cents …

and I was thinking you were the one who did that $100 million dollar jewelry heist

seven acres with cross fence… somewhere around 3.000 to 4,000 feet of fencing

We could not get any V-mesh, which is the best, at any price, so went with the 2" x 4" no climb 5’ tall.

We are using 8’, 2 7/8" pipe for posts, post pounded in every 10’, extensions joints on the top pipes around 60’, corners H braced.

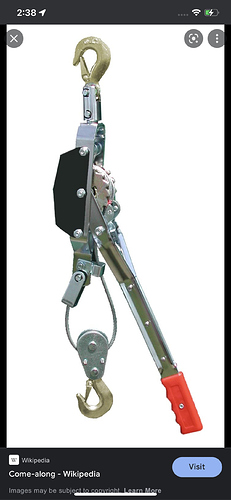

To pull the wire taught, we tied one end well around a corner post, then used before two 2" x 4" lumber, the wire sandwiched between them, both bolted together and pulled on two points with a chain and come-along winch.

This time we had two spare metal angle irons the right size, so we used those like we used the 2" x 4" before. We have put up some 1000’ now.

If someone knows how to do it and has prepared all they need beforehand, putting such fence up goes very fast and is satisfying to see all your work once finished.

This!

I had no choice, just me here & at age 54 working 4/D/W, no way I could have fenced my 2 pastures.

Small as they are - 1/2ac & 1+ac - the work was beyond my ability.

8’ long, 6" round posts, set 12’ apart. Pounded in by a post driver.

Coated tensile wire, 3 lines beneath a 4" rail (Centaur clone). Top line can carry a charge, I’ve never put a charger on it.

Went up in 3 days.

Pricy? Hell YES!

Worth it? Absolutely.

18yrs later I have had a total of 3 splices needed (2 of those this year).

If I’d made that line hot, chances are no repairs would be needed.

It’s where the horses stick their heads through for the “greener” grass, then pull back

Maybe a dozen posts leaning due to ground heaving, 1 post in a not-emergent location needing to be replaced.

I don’t recommend DIY horse fencing unless you’re under 40 or in very good shape.  It is extremely hard work. But absent that, you need a contractor who knows what they’re doing. I have seen some photos where the non-climb was just wrapped around and stapled to the end post.

It is extremely hard work. But absent that, you need a contractor who knows what they’re doing. I have seen some photos where the non-climb was just wrapped around and stapled to the end post.

To do it right, you unlock the knots, slide a bunch of the vertical wires off, then wrap each horizontal wire around the post and back to itself. Tedious and hard on the hands, even with the magic tool from Red Brand:

171001_6729 by Wendy, on Flickr

171001_6729 by Wendy, on Flickr

(that was from a repair job)

Is 3 rail wood fence wrong? Pressure treated lumber for a 3 board fence that includes 1 4x4 post is roughly $33 every 8’.

4x4s aren’t really large enough for horse fence. Look at pressure treated 4x6s & rough cut oak 1x6x16 ft for three board rail.

that is what we switch to using since the 4by6 has much less tendency to twist as they dry …to date, none that we have used have distorted at all