We’re in the middle of a long project at our little farmette, the end result of which will be water and power to all the outbuildings. We’re at the phase of the project where I need to give serious thought to lighting in the barn.

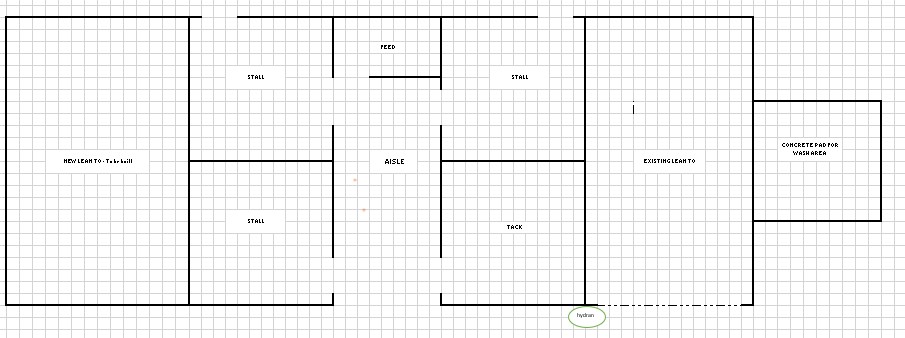

It’s a small barn, 24’ x 36"; three stalls, a tack room and tiny feed room. I’ve attached the layout if anyone’s interested.

I have very specific ideas about where electric outlets should go (though please weigh in on that as well) but am struggling about lighting.

I know I want an overhead light in every stall and the feed room, lots of light in the tack room to see to clean tack, and really good bright lights in the aisle for grooming and clipping, but that’s as far as I’ve gotten.

What would the COTH hive mind recommend? Or avoid like the plague?